A safelight is a clean light

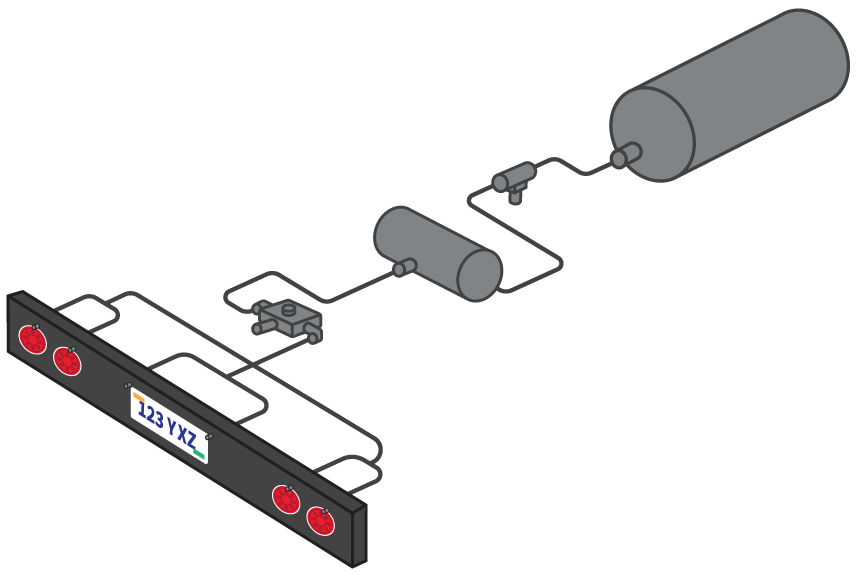

The Safe Light Cleaning System uses compressed air, stored in a dedicated receiver installed in the undercarriage of a trailer or tractor, to periodically, predictably and autonomously clean lights with a short duration air burst.

The benefits for trailer fleets running this system include: increased safety for truck drivers & the driving public, increased convenience/efficiency, decreased insurance premiums for fleets, regulatory compliance, market differentiation, public & industry relations goodwill, and the flexibility to adapt the system to keep any crucial surface clean such as cameras, sensors, mirrors, license plates, and the like.

PROBLEM IDENTIFICATION

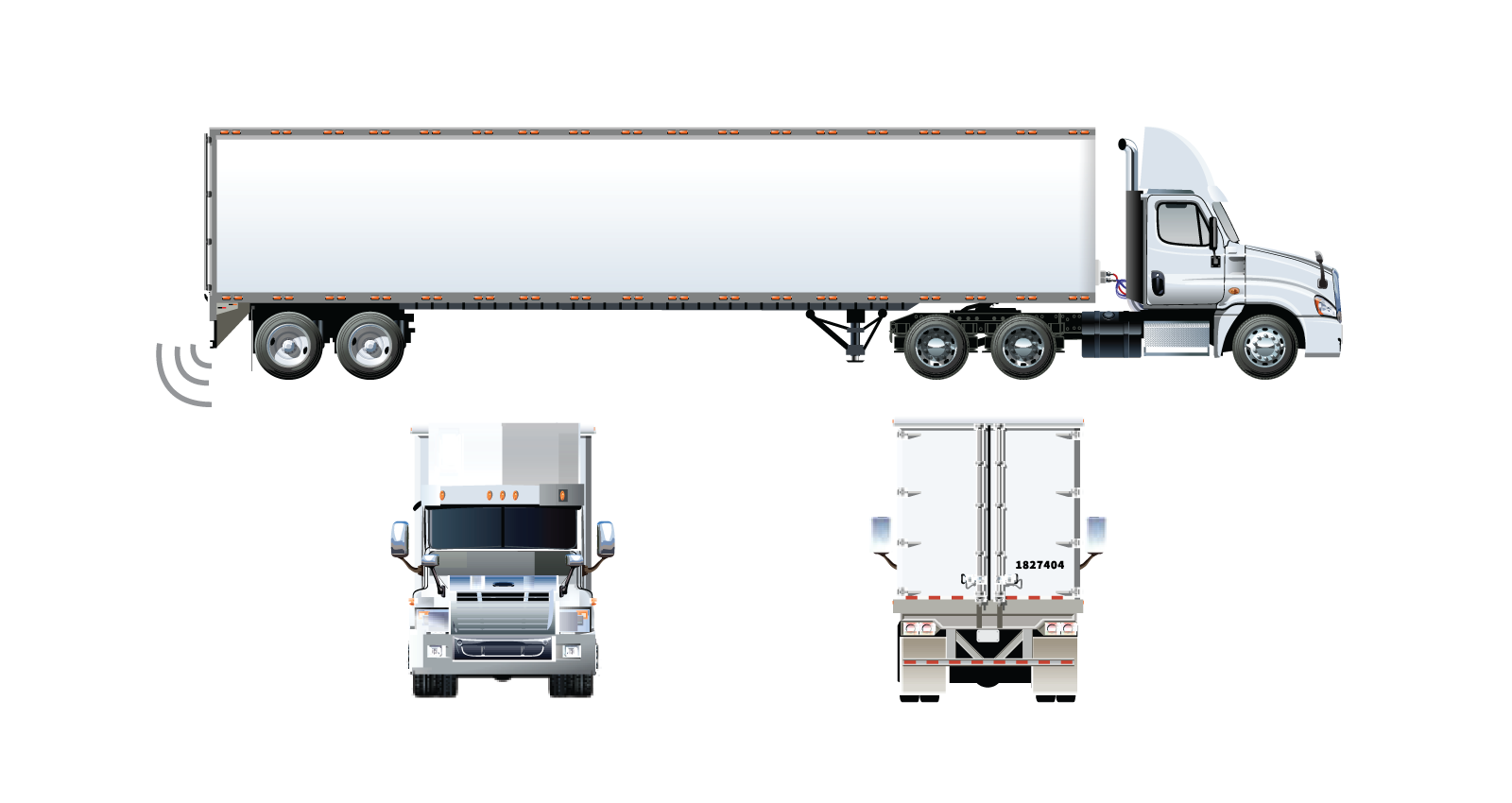

Truck-trailers operating in challenging conditions, especially in long-haul and resource sectors in northern climates, experience road conditions that obscure their marking-brake lights (fouling) with snow, ice, mud, dirt, and dust. Federal and provincial vehicle safety legislation mandate that all vehicles have clearly visible lamps and reflectors, both in the front and in the rear, at all times. Compliance is difficult, near impossible to maintain, and results in non-compliance of a regulatory safety mandate.

Fouled lights increase the risk of collisions from the rear as the trailers become ‘phantom vehicles’ that are difficult to spot, especially in challenging winter conditions. The safety risk to both drivers of the vehicle and the driving public is elevated when lights are fouled.

The Safe Light Cleaning System benefits from a patented system that is simple, safe, autonomous, cost-effective, and already validated in challenging field conditions.

Safe Brake Lights

SAFE BRAKE LIGHTS

Seamless integration

Seamless integration

Other Uses

Other Uses

Regulatory Compliance

Safety

Efficiency

Insurance

Market Differentiation

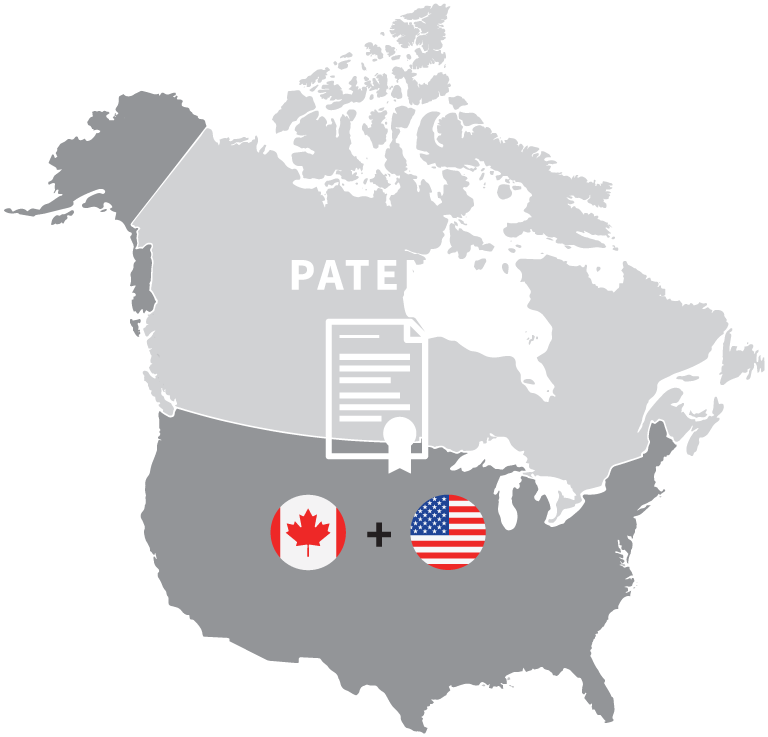

North American Patent

Safe Light Cleaning System (SLCS) owns the CDN and US patents for an autonomous air cleaning system for the transportation industry. The system connects to compressed air brake tanks on commercial transportation trailers and draws on excess air to power an automatic, compressed air cleaning system for the vehicle’s lights, particularly the rear marking-brake lights. The patent also covers broader applications to keep any surface clean on a truck/trailer, using

the aforementioned method, such as cameras, sensors/LIDAR, mirrors, license plates & ID #’s, or any other surfaces that requires a clean surface during operation.

Strategic Partners

Safe Light is seeking the opportunity to partner with leaders in the transportation industry with a demonstrated track record of automation and safety innovation. SLCS is actively seeking select partners within:

- Fleet, Freight, Long Haul Transportation

- Oil and Gas, Forestry, Agriculture, Mining

- Trailer Manufacturing

- Parts/Components Manufacturing: Lighting, Valves, Air Brakes

- Fleet Insurance Industry

The SLCS patents cover both Canada and the US, representing a significant market opportunity when considering the trailer output for new (OEM) builds in addition to the existing market of fleet with aftermarket retrofit kits.

We invite industry collaboration as SLCS enters the next phase of commercialization.

Target Market

INDEPENDENT TESTING & VALIDATION

Safe Light has been tested and proven in the field, independently, and is ready for the next phase of independent testing and validation in both the shop and field operational environments. Through 2020 and early 2021, SLCS will be working with a select number of strategic industry partners to trial the system in the field, work with the system in the shop, and to provide feedback with the goal of advancing the system from ‘Technology Readiness Level’ 7 to 9:

Prototype ready for demonstration in an appropriate operational environment. Prototype at planned operational level and is ready for demonstration in an operational environment. Activities include prototype field testing. Through the testing & validation pilot program, Safe Light will work with its strategic partners to gather operational feedback regarding final iterations and improvements required to advance the system to a commercial-ready level 9.

Actual technology proven through successful deployment in an operational setting. Actual application of the technology in its final form and under real-life conditions, such as those encountered in operational tests and evaluations. Activities include using the innovation under operational conditions.